Cabinet Solutions CNC Workshop (Workshop for short) takes all of the guesswork out of using a CNC program. You can go from designing a kitchen, to setting up tooling infomation, to EnRoute for nesting parts and creating G-Code in moments. And the best part? This information needs to only be set up once! Only new material would require you to go in and make any changes to the Board Routing, Material Tools Settings and Real Material Thickness sections.

Using the Workshop you can set up the same bit to go through different material types with varying thicknesses with ease. Change the Feed Rate and the spindle speed per material and you'll cut down on how fast a bit can carve through material, saving you bit wear/tear, and eliminating chip-out to give you a smooth cutting part.

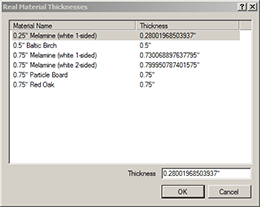

The Workshop has a feature in it for adjusting the real material thickness of the materials by up to .05" +/- to allow for swelling and contracting of the material types due to moisture in the air, time of year, etc.

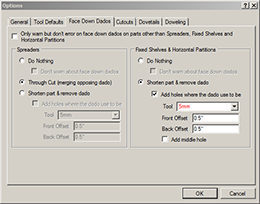

Since your machine can only cut from one side when cutting partitions that have dados on both sides, the Workshop offers solutions as to how to handle those cuts.

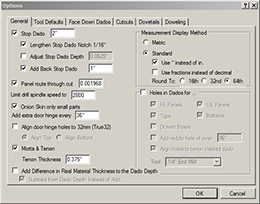

Combining 2 concepts together, any cabinet can be made handed (only able to be put together one way). First we have the Stop Dado. This is where you specify the distance from the front and/or back of a part (bottoms, tops, fixed shelves, and spreaders/stretchers) so when the parts get edge banded, the Edge Bander can smoothly work without bouncing off of an already cut dado, causing damage to the part, or your machine. The back side stop dado is needed to create a Mortise and Tenon (Qualified Tenon) Joint. Simply specify the thickness of the tenon and the mortise will adjust accordingly.

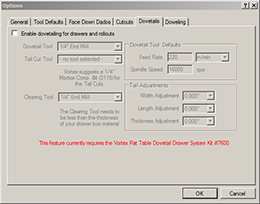

Dovetail drawers couldn't be easier in the Workshop. No longer needing to measure your dovetail drawers in certain increments to make sure that a dovetail gets cut off, our software can dovetail any size drawer box.

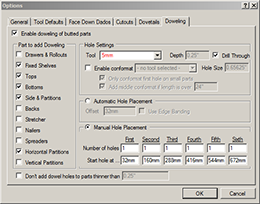

Doweling can be set up in the Workshop to fit any butt jointed parts. You can set up a line bore pattern for them or set up custom distances that will fit any dowel machine. If the dowel holes are longer than the part, the software ignores them so parts don't get doweled by mistake.

With the various types of drawer slides on the market today, we have several templates available from Blum, Salice, Vitus and more. You can create your own hole pattern templates as needed or if a type you are looking for isn't listed and you'd like one to be made, send the spec sheet over to Tech Support and we can generate one for you. Keep in mind that all of the slides we have listed are to manufacturer specifications.